Applications:

Used in metallurgical, mining, casting, mechanical & transportation industries for hoisting magnetic conductive materials like steel.

Features:

>Completely sealed welding structure, good humidity resistance;

>Reasonable magnetic path designing, quality low carbon steel plates, excellent mica with heat conductivity & heat resistance, all contributed to the thermal state working efficiency of lifting magnet;

>Optimized designing & special fabrication process enhanced the electric & mechanical characteristics of magnet exciting coil;

> Normal type lifting magnet: the electrified sustaining rate reaches 60% and ensures the working efficiency;

> Megathermal type lifting magnet: special heat insulation method is adopted, the temperature of attracted material exceeds 700 degree.

|

|

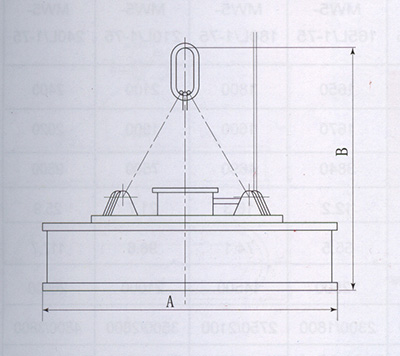

| MW5 LIFTING MAGNET (DURATION FACTOR TD-60%, DC-220V) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Dimensions | Weight (kg) | Power (kW) | Cold Current (Amp) | Capacity (kg) | |||

| A | B | Steel Ball | Cast Iron Ingot | Steel Scrap | ||||

| MW5-70L/1 | 700 | 800 | 500 | 3.2 | 14.7 | 2500 | 380/200 | 120/100 |

| MW5-110L/1 | 1100 | 1080 | 1250 | 7 | 35.1 | 6500 | 1000/800 | 450/400 |

| MW5-130L/1 | 1300 | 1210 | 2050 | 11.9 | 54 | 8500 | 1400/1100 | 700/600 |

| MW5-150L/1 | 1500 | 1220 | 2700 | 15.6 | 71 | 11000 | 1900/1500 | 1100/900 |

| MW5-165L/1 | 1650 | 1230 | 3400 | 19.8 | 90 | 13000 | 2300/1800 | 1350/1040 |

| MW5-180L/1 | 1800 | 1470 | 4100 | 22.4 | 102.4 | 14500 | 2750/2100 | 1600/1350 |

| MW5-210L/1 | 2100 | 1800 | 6800 | 27.9 | 127 | 17000 | 3200/2500 | 2000/1600 |

| MW5-240L/1 | 2400 | 2020 | 9000 | 33.9 | 154 | 26000 | 4800/3800 | 2850/2250 |